Glow in the dark pigment is a product sintered in reducing atmosphere. Its luminescence is mainly due to the physical thermoluminescence produced by the low valence electron energy level transition of rare earth elements.

Sintered ceramics need to be in an oxidizing atmosphere. If Glow in the dark pigment is directly applied, it will be oxidized, rare earth elements will be oxidized and become a high price state, and then the function of glow pigemnt powder will be lost.

Therefore, there are only three ways to makeGlow in the darkt ceramics:

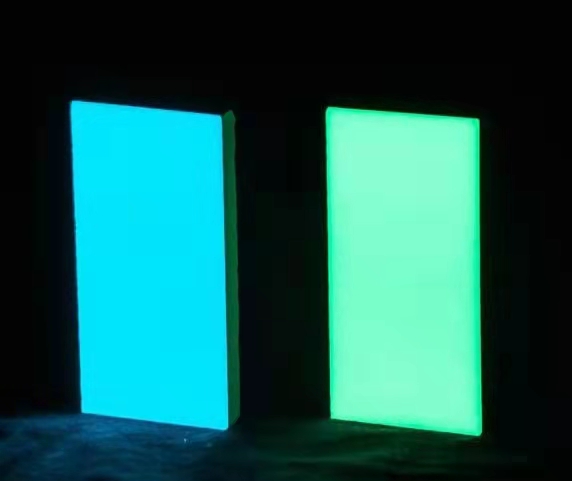

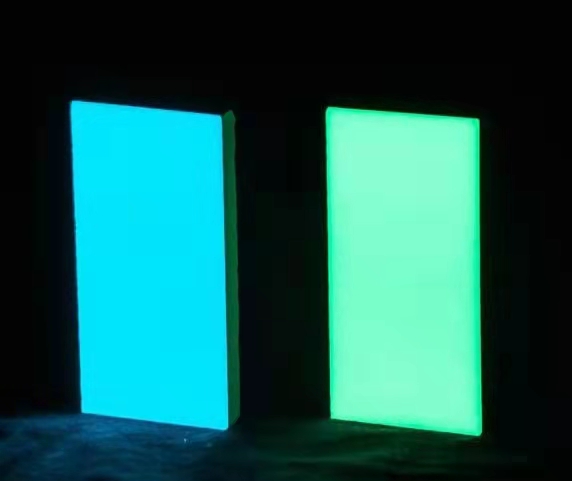

1、 The dosage of Glow in the dark pigment is generally between 30% - 50%. After mixingGlow in the dark pigment with some transparent paints, it is coated on the ceramic surface. In this way, there is no oxidation sintering process, so glow in the dark powder will not be damaged. However, due to the presence of paint, it is also a ceramic, which loses the original glaze effect.

2、 Use Glow in the dark ceramic glaze. This Glow in the dark ceramic glaze is a special luminous product. In the low temperature stage, the glaze will liquefy quickly, seal the Glow in the dark pigment and no longer contact with oxygen, so it can ensure the luminous effect to a certain extent. However, even for Glow in the dark ceramic glaze, the lower the sintering temperature and the shorter the sintering time, the better the luminous effect. It is more suitable for building ceramics, such as wall tiles and waist lines.