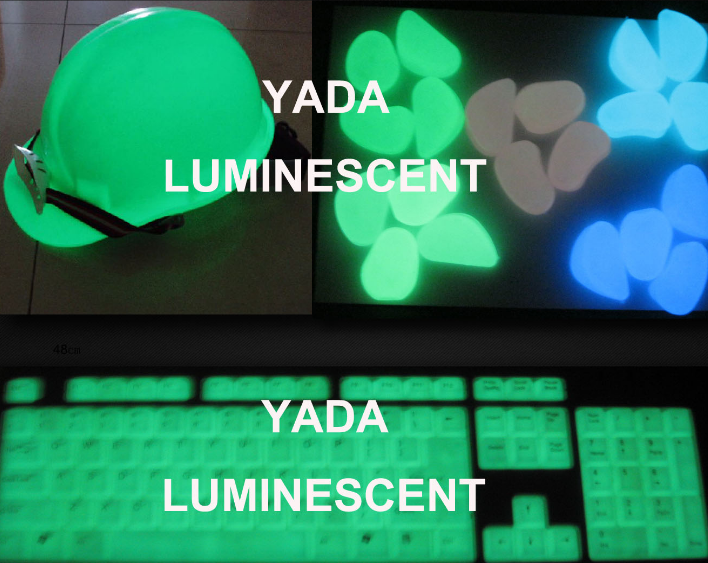

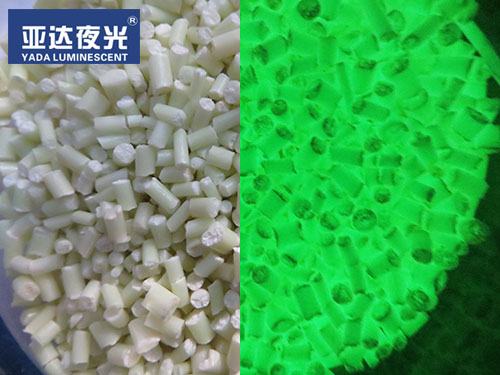

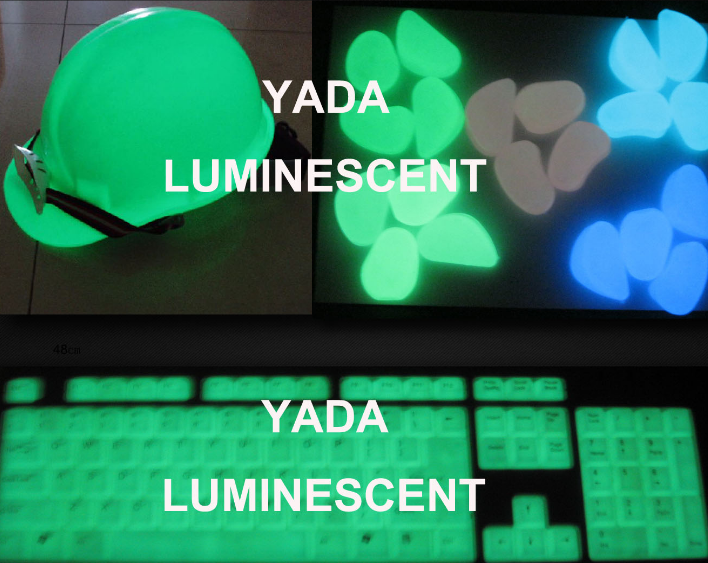

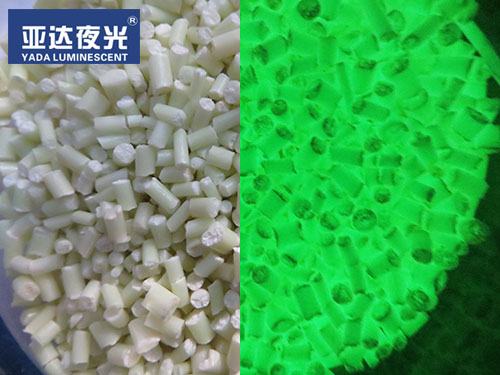

YADA luminescent powder also called glow powder Strontium Aluminate is commonly used for injection molding: PP, PC., PE, ABS and other transparent resins or plastic materials with good transparency, But it's often the problem of blackening,This use problem is inevitable, but it can reduce its occurrence.

1. High speed mixing of metal is not allowed in the mixing process of luminous powder. Chemical reaction will occur when luminous powder is in contact with metal for a long time, and it will turn black. Stir it in a container with non-metallic lining, so as to reduce the wear of luminous powder as much as possible. It is recommended to use manual mixing.

2. Diffusion oil is added during the material mixing process, which can reduce the friction between luminous powder and screw.

3. The discharging time shall be shortened as much as possible.

4. Check the smoothness of the screw before production to ensure the smoothness of the screw

5. Wuxiyada luminous powder has the characteristics of fine particle size, high brightness, good dispersion and small addition. Its luminous time is more than 10 times longer than that of ordinary luminous powder. It has good weather resistance and can be used indoors and outdoors.